Media

Image

Media Name

The unit 2 and 3 trash rack guides are under the winter hoardings and work continues to complete intake units 4 and 5. | March 2023

Caption

The unit 2 and 3 trash rack guides are under the winter hoardings and work continues to complete intake units 4 and 5. | March 2023

Media

Image

Media Name

Installing rebar on the approach channel wall for pouring concrete. | March 2023

Caption

Installing rebar on the approach channel wall for pouring concrete. | March 2023

Media

Image

Media Name

After concrete is poured, the approach channel wall is covered with winter hoardings to allow concrete to cure. | March 2023

Caption

After concrete is poured, the approach channel wall is covered with winter hoardings to allow concrete to cure. | March 2023

Media

Image

Media Name

Workers regularly climb the 17-storey staircase at the centre block of the spillway headworks. | March 2023

Caption

Workers regularly climb the 17-storey staircase at the centre block of the spillway headworks. | March 2023

Media

Image

Media Name

Installing the formwork to pour concrete on the west end of the approach channel wall. | March 2023

Caption

Installing the formwork to pour concrete on the west end of the approach channel wall. | March 2023

Media

Image

Media Name

Workers build an access walkway in advance of the next concrete pour for the auxiliary spillway. | March 2023

Caption

Workers build an access walkway in advance of the next concrete pour for the auxiliary spillway. | March 2023

Media

Image

Media Name

The end wall of the auxiliary spillway as it transitions into the slurry wall. This is a trench filled with a concrete mix and rebar (slurry) down to bedrock to prevent water seepage. | March 2023

Caption

The end wall of the auxiliary spillway as it transitions into the slurry wall. This is a trench filled with a concrete mix and rebar (slurry) down to bedrock to prevent water seepage. | March 2023

Media

Image

Media Name

Installing reinforcing steel on the auxiliary spillway. | March 2023

Caption

Installing reinforcing steel on the auxiliary spillway. | March 2023

Media

Image

Media Name

Levelling of the zone 8 material on the upstream shell of the dam. | March 2023

Caption

Levelling of the zone 8 material on the upstream shell of the dam. | March 2023

Media

Image

Media Name

Working on the permanent debris boom. | March 2023

Caption

Working on the permanent debris boom. | March 2023

Media

Image

Media Name

Where the Moberly and Peace rivers meet upstream of the dam, the debris boom can be seen, along with the inlet portal where the river flows around the dam. | March 2023

Caption

Where the Moberly and Peace rivers meet upstream of the dam, the debris boom can be seen, along with the inlet portal where the river flows around the dam. | March 2023

Media

Image

Media Name

The spillway basin below the auxiliary spillway. | March 2023

Caption

The spillway basin below the auxiliary spillway. | March 2023

Media

Image

Media Name

Installing reinforcing steel and formwork to pour concrete on penstock unit 5. Water will flow through six penstocks into the powerhouse to generate electricity. | March 2023

Caption

Installing reinforcing steel and formwork to pour concrete on penstock unit 5. Water will flow through six penstocks into the powerhouse to generate electricity. | March 2023

Media

Image

Media Name

This gantry crane lifts the intake gates. It is on rails to allow movement between intake units 1 through 6. | March 2023

Caption

This gantry crane lifts the intake gates. It is on rails to allow movement between intake units 1 through 6. | March 2023

Media

Image

Media Name

Equipment is brought to the main service bay in the powerhouse to be used for installation. | March 2023

Caption

Equipment is brought to the main service bay in the powerhouse to be used for installation. | March 2023

Media

Image

Media Name

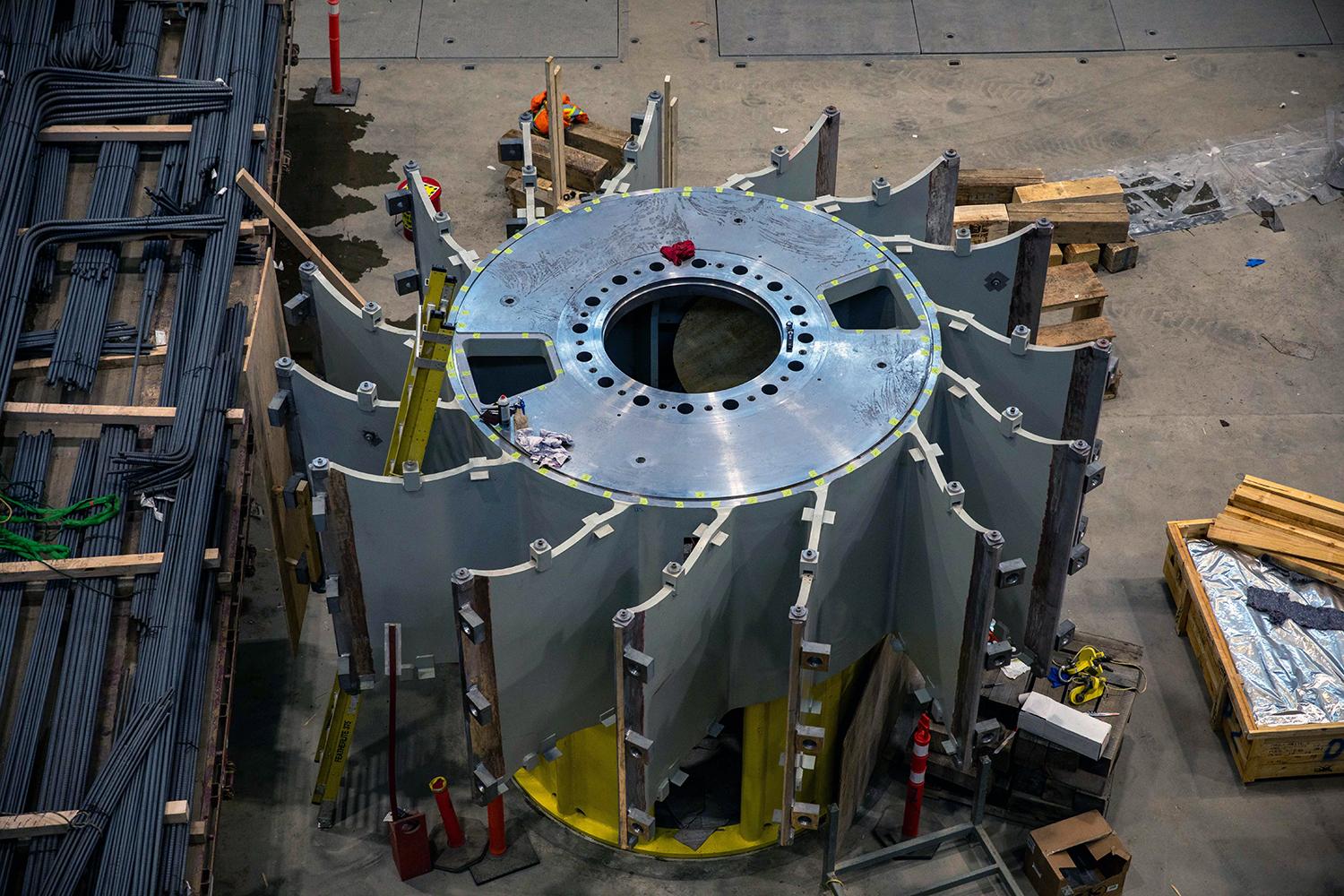

The centre section of unit 3 rotor assembly is in the main service bay of the powerhouse ahead of installation. | March 2023

Caption

The centre section of unit 3 rotor assembly is in the main service bay of the powerhouse ahead of installation. | March 2023

Media

Image

Media Name

The asphalt and sub-base gravel from the original section of Farrell Creek on Highway 29 has been broken and hauled away to be ground and re-used in future road construction. | March 2023

Caption

The asphalt and sub-base gravel from the original section of Farrell Creek on Highway 29 has been broken and hauled away to be ground and re-used in future road construction. | March 2023

Media

Image

Media Name

South-facing view of the Farrell Creek bridge on Highway 29 where the original highway section has been removed and coarse woody debris will be spread. | March 2023

Caption

South-facing view of the Farrell Creek bridge on Highway 29 where the original highway section has been removed and coarse woody debris will be spread. | March 2023

Media

Image

Media Name

Water from the Peace River will flow down the approach channel on the far right and exit the Site C dam downstream. | March 2023

Caption

Water from the Peace River will flow down the approach channel on the far right and exit the Site C dam downstream. | March 2023

Media

Image

Media Name

Construction of the approach channel wall. | March 2023

Caption

Construction of the approach channel wall. | March 2023

Media

Image

Media Name

Water will flow through these six penstocks down into the powerhouse, where it will turn the turbines to make electricity. | March 2023

Caption

Water will flow through these six penstocks down into the powerhouse, where it will turn the turbines to make electricity. | March 2023

Media

Image

Media Name

Water will flow down the approach channel (left) and down through the six penstocks (centre) into the generating station. | March 2023

Caption

Water will flow down the approach channel (left) and down through the six penstocks (centre) into the generating station. | March 2023

Media

Image

Media Name

A downstream view of the approach channel. | March 2023

Caption

A downstream view of the approach channel. | March 2023

Media

Image

Media Name

The spillways are an important safety feature, as they allow the passage of large volumes of water from the reservoir into the river channel downstream. | March 2023

Caption

The spillways are an important safety feature, as they allow the passage of large volumes of water from the reservoir into the river channel downstream. | March 2023

Media

Image

Media Name

At the permanent upstream fish passage, migrating fish will be sorted, tagged, and released past the dam site. | March 2023

Caption

At the permanent upstream fish passage, migrating fish will be sorted, tagged, and released past the dam site. | March 2023

Media

Image

Media Name

Water will exit the generating station to the tailrace and flow downstream. At left, construction is underway on the spillways. | March 2023

Caption

Water will exit the generating station to the tailrace and flow downstream. At left, construction is underway on the spillways. | March 2023

Media

Image

Media Name

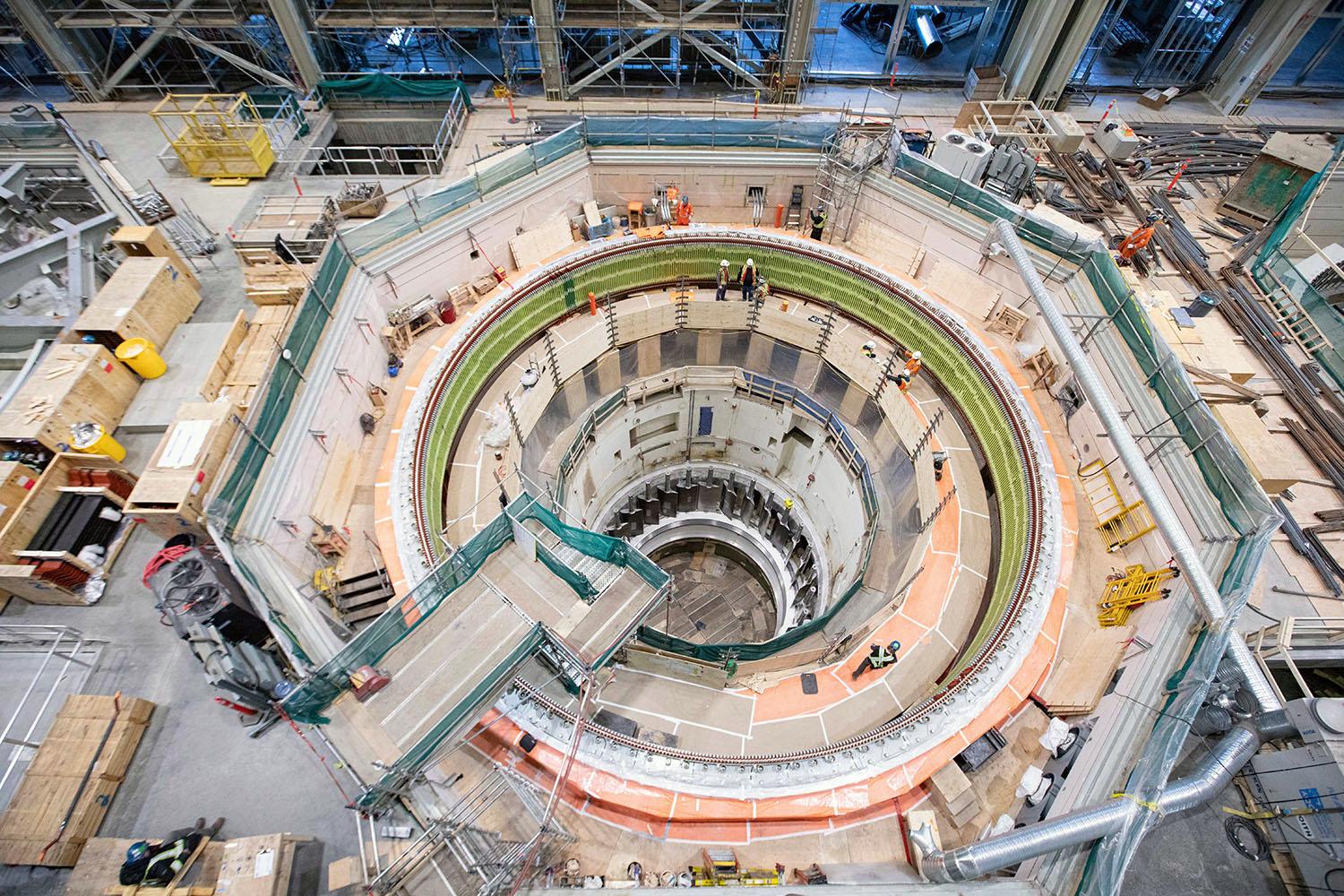

There are six turbine generator units inside the powerhouse. Unit 1 is in the foreground, where the upper bracket is installed. | March 2023

Caption

There are six turbine generator units inside the powerhouse. Unit 1 is in the foreground, where the upper bracket is installed. | March 2023

Media

Image

Media Name

The stator bar is installed for the Unit 2 generator inside the powerhouse. The stator converts the rotating magnetic field into an electrical current. | March 2023

Caption

The stator bar is installed for the Unit 2 generator inside the powerhouse. The stator converts the rotating magnetic field into an electrical current. | March 2023

Media

Image

Media Name

Workers connect a crane to lift the second turbine runner. There will be six turbine runners, each weighing about 165,000 kilograms. | March 2023

Caption

Workers connect a crane to lift the second turbine runner. There will be six turbine runners, each weighing about 165,000 kilograms. | March 2023

Media

Image

Media Name

A crane is connected to a lifting device to install the second turbine runner. The runner is the heaviest single project component. | March 2023

Caption

A crane is connected to a lifting device to install the second turbine runner. The runner is the heaviest single project component. | March 2023

Order

10.00